We are Kol-Heater (Kolkata Heater), a leading industrial heater manufacturer based in Kolkata, delivering high-performance small injection molding machine heater solutions to machine manufacturers and processors across India. Our heaters are engineered for compact injection molding machines where thermal accuracy, energy efficiency, and process stability are essential for production success.

Operating from our manufacturing unit at 309 Rabindra Sarani, Kolkata – 700006, we supply durable, long-lasting industrial heaters nationwide. Our focus is delivering uniform heating performance that ensures reliable molding results in precision plastic processing applications.

Engineered Heating for Small Injection Molding Machines

Small injection molding machines require tight temperature control due to limited barrel capacity and sensitive processing parameters. Our small injection molding machine heaters are built to provide:

- Fast thermal response

- Uniform heat distribution

- Reduced heat loss

- Stable operating temperatures

This level of control helps manufacturers maintain consistent melt viscosity, dimensional accuracy, and repeatable part quality.

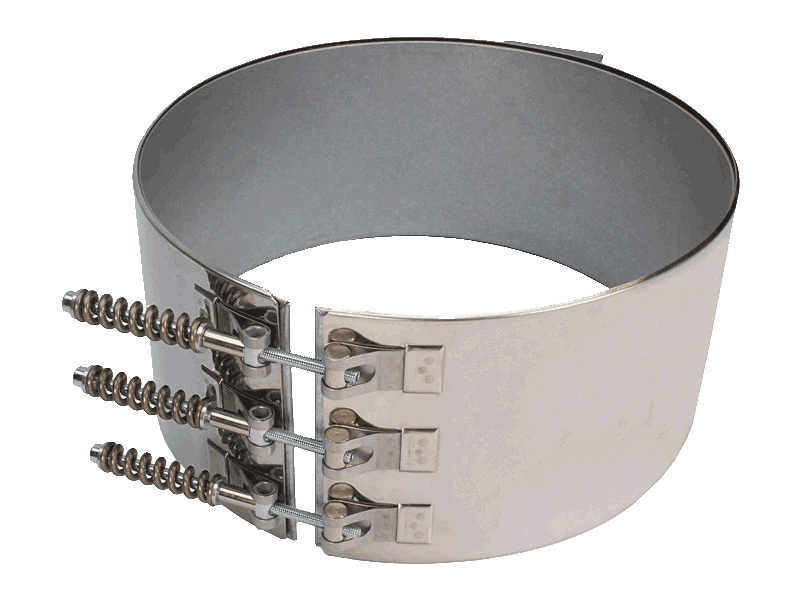

Mica Band Heater for Compact Molding Units

Our mica band heaters are widely used in small injection molding setups because of their compact design and efficient heat transfer. Built using nickel-chromium resistance wire, high-grade mica insulation, and a stainless steel outer cover, these heaters are ideal for temperatures up to 350°C.

Key advantages:

- Rapid heat-up capability

- Tight clamping for better barrel contact

- Cost-effective solution

- Space-saving design

These heaters are particularly effective in the middle heating zones of small barrels where balanced heat transfer is critical.

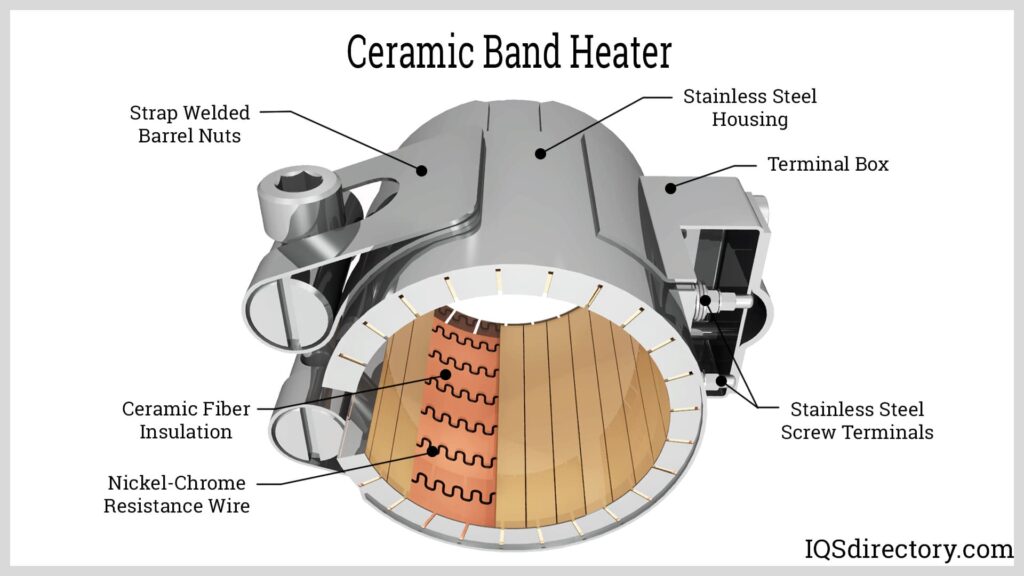

Ceramic Band Heater for High-Temperature Applications

For advanced processing requirements, our ceramic band heaters deliver superior performance through ceramic fiber insulation and optimized heating element placement.

Features include:

- Operating range up to 450°C

- Reduced power consumption

- Lower surface watt density

- Long operational lifespan

Ceramic heaters are ideal for engineering polymers such as polycarbonate, nylon, ABS, and PPS, where stable heating through the middle barrel section is essential to prevent material degradation.

Nozzle Heater for Accurate Melt Flow

The nozzle heater ensures consistent melt temperature at the injection point. Our nozzle heaters prevent common issues such as:

- Freeze-off

- Drooling

- Flow irregularities

Available in mica, ceramic, and mineral insulated (MI) designs, they deliver uniform heating around the nozzle, ensuring smooth plastic flow into the mold.

Key Features of Our Small Injection Molding Machine Heaters

Our heaters are designed with performance-focused construction:

- High dielectric strength insulation

- Precision-engineered resistance coils

- Stainless steel sheathing

- Uniform temperature coverage

- Corrosion-resistant materials

- Optimized watt density

These design factors provide process reliability and extended heater service life.

Advanced Temperature Control Compatibility

We ensure seamless integration with modern temperature control systems:

- J-Type thermocouples

- K-Type thermocouples

- RTD sensors

- PID controllers

Accurate monitoring across barrel zones — including the middle heating area — prevents overheating and maintains polymer quality.

Energy Efficient Heating Technology

Energy savings play a vital role in modern manufacturing. Our heaters are designed for:

- Reduced radiant heat loss

- Better insulation retention

- Optimized electrical consumption

- Faster thermal recovery

This ensures lower operating costs without compromising production performance.

Applications Across Indian Manufacturing Industries

Our small injection molding machine heaters support industries such as:

- Medical device production

- Electronics component molding

- Automotive precision parts

- Consumer goods manufacturing

- Research and development labs

Each application demands stable temperature management, which our heaters deliver consistently.

Customized Heater Manufacturing

We manufacture heaters tailored to exact machine requirements:

- Custom diameters and widths

- Voltage and wattage customization

- Sensor hole provision

- Terminal orientation options

- Special mounting designs

This flexibility ensures perfect compatibility with small-tonnage injection molding machines.

Installation and Maintenance Guidelines

Proper installation maximizes heater life:

- Clean barrel surfaces before mounting

- Ensure even and tight clamping

- Avoid over-tightening

- Confirm correct voltage supply

- Check thermocouple placement

Routine inspections maintain heating efficiency and prevent unexpected downtime.

Safety and Durability

Our heaters are built for safe industrial use:

- High insulation resistance

- Grounded metal sheathing

- Moisture-resistant construction

- Overload protection compatibility

This ensures dependable operation in demanding production environments.

Why Thermal Precision Matters

In small injection molding machines, even minor temperature fluctuations can cause:

- Material degradation

- Inconsistent melt flow

- Dimensional defects

- Surface imperfections

Our heating systems provide stable and uniform heating, especially across the middle barrel zone, ensuring smooth and predictable processing.

Manufacturing Excellence at Kol-Heater

We follow strict quality control standards:

- Precision coil winding

- High-grade insulation materials

- Electrical testing

- Thermal performance validation

This results in long-lasting industrial heaters trusted by machine manufacturers across India.

Nationwide Supply from Kolkata

Although our manufacturing base is in Kolkata, we supply heaters across India with reliable logistics and support.

📍 Kol-Heater (Kolkata Heater)

309 Rabindra Sarani, Kolkata – 700006

📞 +91 9038960476

📞 +91 9836994384

📧 heaterskolkata@gmail.com

We provide dependable heating solutions designed for industrial performance and durability.

Future-Ready Heating Technology

Our focus remains on:

- Enhanced insulation efficiency

- Smart temperature integration

- Extended service life

- Improved energy utilization

We continue advancing heating technology for modern injection molding systems.