We deliver industrial band heaters engineered for precision, durability, and efficiency across demanding manufacturing environments. Designed to provide uniform, controlled heat to cylindrical and curved surfaces, band heaters are essential components in plastic processing, packaging, extrusion, injection molding, petrochemical operations, and food production. Our solutions combine advanced materials, optimized watt densities, and robust construction to ensure consistent thermal performance with minimal energy loss.

What Is an Industrial Band Heater

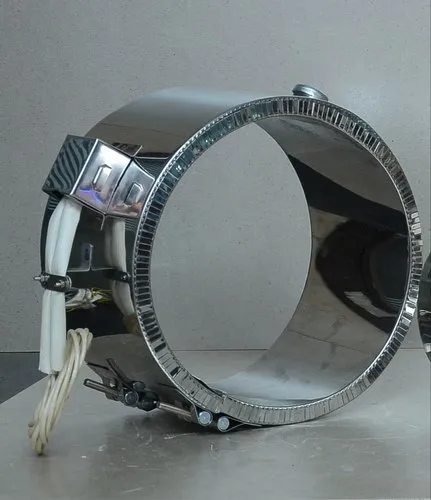

An industrial band heater is a clamp-on heating device that wraps around barrels, pipes, dies, nozzles, and cylinders. It transfers heat directly to the surface through conduction, ensuring fast heat-up times and stable operating temperatures. By maintaining precise thermal control, band heaters enhance process repeatability, improve product quality, and reduce downtime.

Core Benefits of Industrial Band Heaters

Uniform Heat Distribution

We design band heaters to deliver even circumferential heating, eliminating cold spots that compromise process integrity.

Energy Efficiency

Optimized insulation and tight surface contact minimize heat loss, delivering lower power consumption and reduced operating costs.

Long Service Life

High-grade alloys, rugged terminals, and protective sheathing ensure resistance to oxidation, vibration, and thermal cycling.

Process Precision

Accurate temperature control supports tight tolerances, essential for high-value manufacturing and continuous operations.

Types of Industrial Band Heaters

Mica Insulated Band Heaters

Mica band heaters are ideal for applications requiring fast heat-up and moderate temperatures. Their thin profile enables close contact with the heated surface, ensuring rapid thermal response and cost-effective performance.

Key advantages

- Excellent heat transfer

- Lightweight construction

- Reliable performance up to 900°F (480°C)

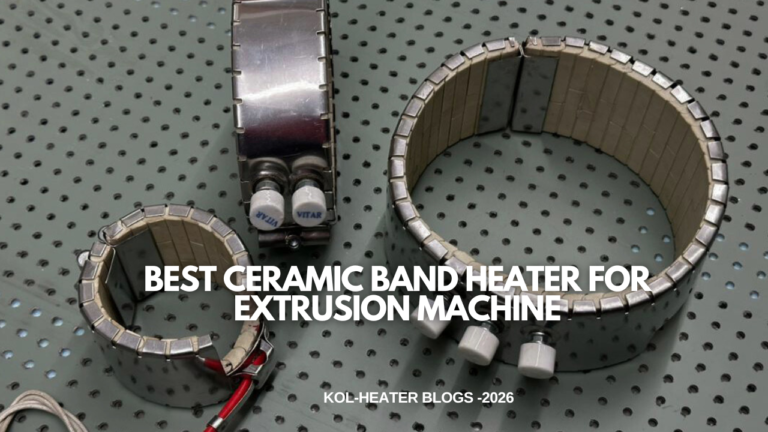

Ceramic Band Heaters

For higher temperature applications, ceramic band heaters provide superior insulation and higher watt densities. Interlocking ceramic tiles retain heat efficiently, making them suitable for extrusion barrels and high-load systems.

Key advantages

- Operating temperatures up to 1400°F (760°C)

- Enhanced energy efficiency

- Reduced heat loss to ambient air

Mineral Insulated Band Heaters

Mineral insulated band heaters excel in extreme environments where durability and precision are critical. Encased heating elements withstand harsh conditions, offering exceptional longevity.

Key advantages

- High vibration resistance

- Uniform temperature control

- Long operational lifespan

Materials and Construction Excellence

Heating Elements

We utilize nickel-chromium resistance wire for stable output and consistent heating under continuous duty cycles.

Sheath and Housing

Premium stainless steel, Incoloy, and brass options provide corrosion resistance and mechanical strength, tailored to specific applications.

Insulation Systems

Advanced insulation materials, including mica and ceramic fiber, ensure optimal heat retention and safety compliance.

Applications Across Industries

Plastic Processing

Band heaters are indispensable for injection molding machines, blow molding systems, and extruders, maintaining precise barrel temperatures for consistent melt flow.

Packaging and Automation

Uniform heating supports sealing, forming, and labeling processes, ensuring production efficiency and product integrity.

Chemical and Petrochemical

Robust designs handle high temperatures and aggressive environments, supporting reactors, pipelines, and processing vessels.

Food and Beverage

Sanitary construction options meet industry standards while delivering controlled heating for processing and packaging equipment.

Customization and Engineering Precision

We offer custom industrial band heaters designed to exact specifications, including:

- Inner diameter and width

- Wattage and voltage

- Integrated thermocouples

- Terminal orientation and lead options

- Insulated or uninsulated housings

Custom engineering ensures perfect fit, maximum efficiency, and seamless integration into existing systems.

Installation and Maintenance Best Practices

Proper Installation

Correct clamping pressure ensures optimal surface contact. Even torque prevents hot spots and extends heater life.

Temperature Control

Pairing band heaters with PID controllers and thermocouples enhances accuracy and protects equipment from overheating.

Routine Inspection

Regular checks for loose terminals, insulation wear, and surface contamination preserve performance and safety.

Performance Metrics That Matter

- Watt Density Optimization for rapid heat-up

- Thermal Stability under continuous operation

- Electrical Safety Compliance

- Reduced Downtime through durable construction

Our heaters are tested to meet strict industrial standards, ensuring reliability in mission-critical applications.

Why Choose Our Industrial Band Heaters

We combine engineering expertise, premium materials, and rigorous quality control to deliver heaters that outperform alternatives. Our focus on efficiency, longevity, and precision helps manufacturers achieve higher productivity with lower total cost of ownership.

Future-Ready Heating Technology

As manufacturing evolves, we continue to innovate with energy-saving designs, smart temperature integration, and advanced insulation technologies. Our industrial band heaters support sustainable operations while maintaining uncompromised performance.

Conclusion

Industrial band heaters remain a cornerstone of modern manufacturing, delivering reliable, efficient, and precise heating across diverse industries. With advanced materials, customizable designs, and proven performance, our solutions empower manufacturers to optimize processes, reduce energy consumption, and achieve consistent results at scale.