As a leading ceramic band heater bulk supplier, we at Kol-Heater (Kolkata Heater) manufacture high-performance industrial heating elements designed for demanding production environments. Based in Kolkata, our advanced manufacturing unit produces durable, energy-efficient, and precision-engineered heaters that support machine manufacturers across India. While our production facility operates from Kolkata, our supply network ensures timely delivery nationwide.

We specialize in bulk manufacturing of ceramic band heaters that meet the exacting requirements of OEMs, plastic processing units, packaging equipment manufacturers, and heavy industrial machinery builders. Our commitment is straightforward: consistent quality, dependable supply, and long-lasting thermal performance.

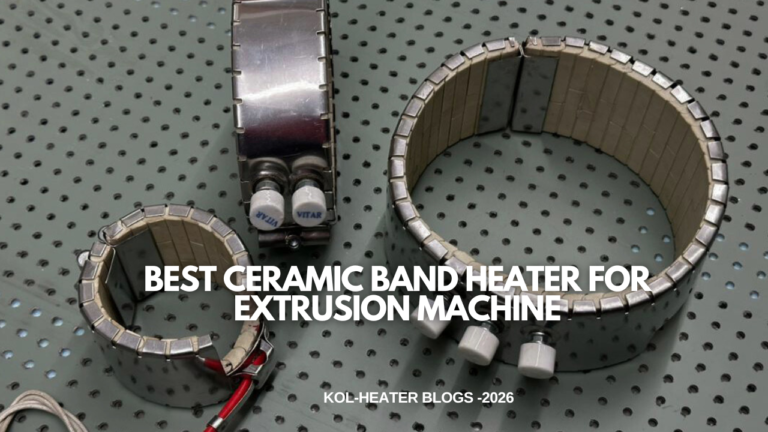

High-Performance Ceramic Band Heaters Engineered for Industrial Efficiency

Our ceramic band heaters are engineered to operate at elevated temperatures with stable and uniform heat distribution. Built using high-grade ceramic insulation and nickel-chromium resistance wire, our heaters ensure optimal thermal efficiency while minimizing energy loss.

Uniform Heat Distribution

The ceramic insulation retains heat effectively, enabling consistent barrel temperature control. This precision supports stable processing conditions in extrusion and molding applications.

High Temperature Capability

Our ceramic band heaters operate efficiently up to 600°C, making them suitable for high-demand industrial heating processes.

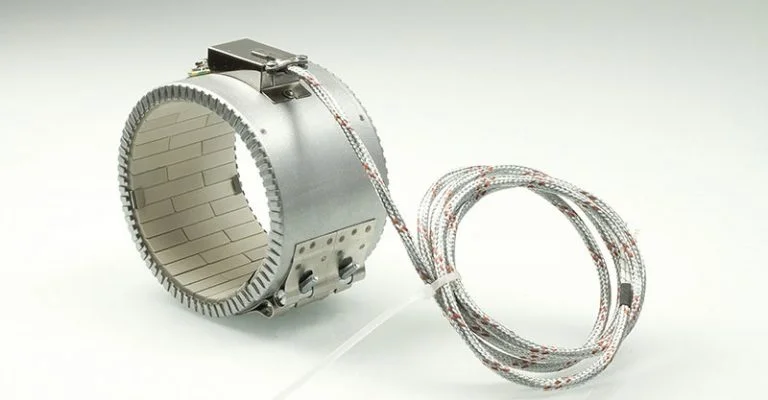

Stainless Steel Outer Sheathing

Each heater is encased in corrosion-resistant stainless steel, protecting against mechanical stress, oxidation, and prolonged exposure to industrial environments.

Bulk Manufacturing Capabilities Designed for Large-Scale Industrial Supply

As an established ceramic band heater bulk supplier, we maintain production systems optimized for high-volume orders without compromising technical precision.

Streamlined Production Process

Our Kolkata manufacturing unit is equipped with specialized tooling and calibrated testing equipment. We ensure accurate coil winding, proper insulation layering, and robust assembly for every heater.

Batch Consistency and Quality Control

Every batch undergoes rigorous inspection protocols, including:

- Electrical resistance testing

- Insulation resistance measurement

- High-voltage dielectric strength testing

- Dimensional accuracy verification

- Surface finish inspection

This structured approach ensures uniform quality across bulk shipments.

Timely Nationwide Distribution

From Kolkata, we dispatch heaters to clients across India. Our logistics framework ensures secure packaging and punctual delivery for OEMs and machine manufacturers.

Custom Ceramic Band Heater Solutions for Machine Manufacturers

Industrial machinery requires heaters tailored to specific barrel dimensions and electrical configurations. We manufacture customized ceramic band heaters in:

- Various inner diameters

- Multiple width options

- Custom watt densities

- Specific voltage ratings

- Integrated thermocouple slots

- Terminal box or lead wire configurations

Our engineering team collaborates directly with machine manufacturers to deliver heating elements that align precisely with machine assembly requirements.

Applications of Ceramic Band Heaters Across Industries

Our ceramic band heaters support multiple industrial sectors where controlled heating is critical for operational performance.

Plastic Extrusion and Injection Molding

In plastic processing machinery, stable barrel heating ensures uniform melting and shaping of polymers. Our heaters maintain accurate temperature control to enhance production consistency.

Blow Molding Equipment

Consistent thermal output is essential for blow molding operations. Our ceramic band heaters provide steady heat distribution across barrels.

Packaging Machinery

Heat sealing and forming operations depend on reliable heating systems. Our heaters deliver stable output to maintain production accuracy.

Rubber Processing Units

Rubber molding and processing demand high and consistent heat levels. Our heaters operate under continuous load without performance degradation.

Chemical and Industrial Processing Equipment

Industrial heating systems require durable components capable of sustained high temperatures. Our ceramic band heaters meet these demands effectively.

Energy-Efficient Heating for Reduced Operational Costs

Energy consumption directly influences industrial profitability. Our ceramic band heaters are engineered for thermal retention and minimized heat loss. The ceramic insulation layer enhances heat efficiency, reducing power consumption while maintaining high output performance.

By improving heat transfer efficiency, our heaters contribute to lower electricity usage and extended service life, ensuring long-term cost benefits for machine manufacturers.

Why Kol-Heater (Kolkata Heater) Stands Out as a Ceramic Band Heater Bulk Supplier

Manufacturing Expertise in Industrial Heaters

With extensive experience in heater production, we focus on durability, performance consistency, and technical precision. Our manufacturing processes are structured to deliver reliable industrial heating solutions.

Nationwide Industrial Reach

Although based in Kolkata, we supply ceramic band heaters to clients across India. Our operations are designed to support machine manufacturers in multiple industrial hubs.

Long-Lasting Product Performance

We design heaters to withstand high temperatures, continuous usage, and demanding industrial conditions. Our materials and manufacturing standards ensure extended operational life.

Competitive Bulk Pricing

As direct manufacturers, we eliminate intermediary costs. This allows us to offer competitive pricing for bulk ceramic band heater orders without compromising on quality.

Technical Specifications of Our Ceramic Band Heaters

Our ceramic band heaters are manufactured with precise technical parameters:

- Maximum operating temperature: Up to 600°C

- Outer sheath material: Stainless steel

- Insulation: High-density ceramic fiber

- Resistance wire: Nickel-chromium alloy

- Watt density: Customizable

- Voltage options: As per client requirement

- Mounting systems: Adjustable clamping mechanisms

Every unit is calibrated to meet industrial-grade electrical safety standards.

Reliable Industrial Partner for Long-Term Supply

As a professional ceramic band heater bulk supplier, we prioritize reliability, technical accuracy, and consistent performance. Our manufacturing base in Kolkata ensures quality control oversight, while our nationwide supply network ensures seamless distribution.

Machine manufacturers rely on heating systems that perform consistently under demanding conditions. Our ceramic band heaters are engineered to deliver stable output, energy efficiency, and mechanical durability for industrial operations across India.

For bulk ceramic band heater requirements, we provide precision-engineered solutions backed by manufacturing expertise and dependable service.