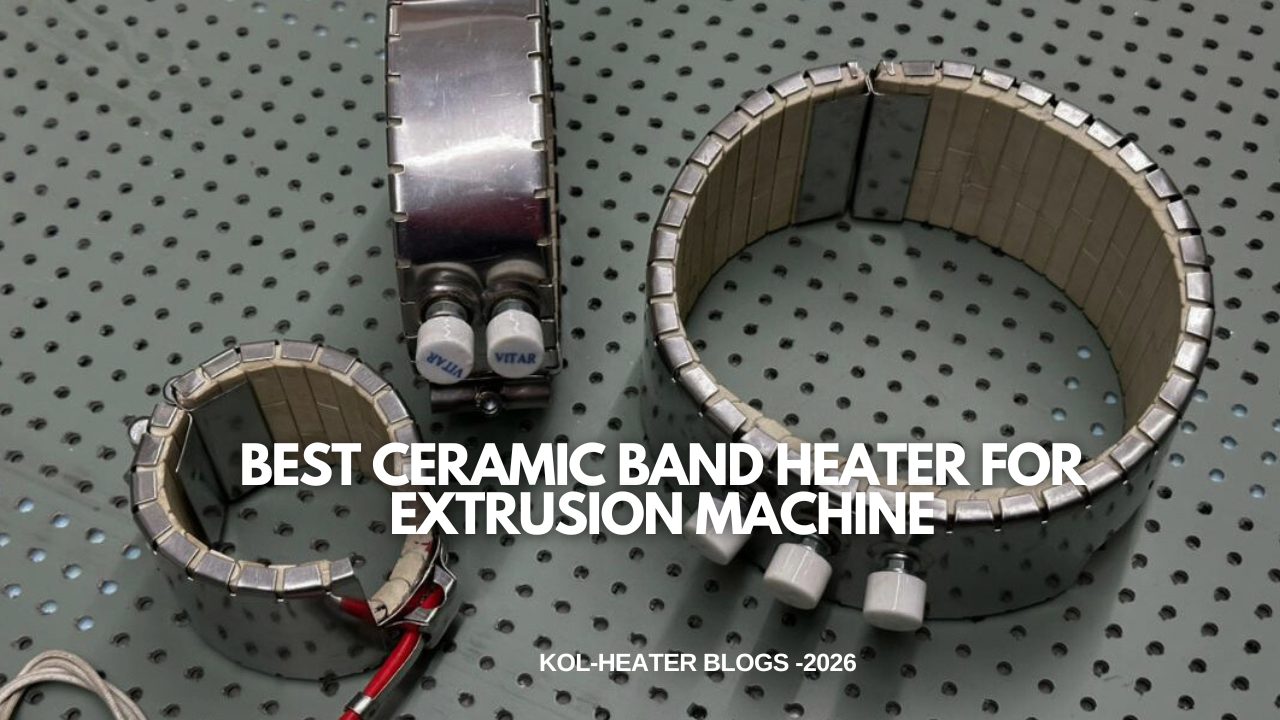

In modern plastic processing, precision heating is the foundation of consistent production quality. We understand that selecting the best ceramic band heater for extrusion machine applications directly affects melt consistency, energy efficiency, machine lifespan, and overall output stability. Our engineering approach focuses on delivering high-performance ceramic band heaters that provide uniform heat transfer, rugged durability, and long operational life under demanding industrial conditions.

Extrusion processes require stable barrel temperatures across multiple zones. Any fluctuation can lead to poor melt flow, dimensional inconsistencies, surface defects, or material degradation. We design our ceramic band heaters for extrusion machines to ensure accurate temperature control, fast heat-up cycles, and superior insulation efficiency.

Why Ceramic Band Heaters Are Ideal for Extrusion Machines

We use ceramic band heaters because they outperform traditional mica heaters in high-temperature and high-duty environments. Extrusion machinery runs continuously, often under heavy load, making it essential to use heating elements that maintain performance over long production cycles.

Key advantages include:

- Higher operating temperatures without insulation breakdown

- Better heat retention due to ceramic fiber insulation

- Reduced energy loss through efficient thermal containment

- Longer service life in harsh industrial environments

- Improved resistance to vibration and mechanical stress

Our extrusion machine ceramic band heaters are engineered with interlocking ceramic tiles that house the heating coil securely while providing expansion flexibility, preventing premature failure.

Advanced Construction for Maximum Performance

We manufacture each ceramic band heater for extrusion machine barrels using a layered construction method that maximizes thermal efficiency and mechanical durability.

1. High-Temperature Resistance Wire

We use premium nickel-chromium resistance wire that provides consistent heat output and maintains electrical stability even under prolonged high-temperature operation.

2. Interlocking Ceramic Insulation

Our ceramic insulation blocks reduce heat loss while allowing the heater to expand and contract safely during thermal cycles. This structure ensures durability and long-term performance.

3. Stainless Steel Outer Sheath

The stainless steel jacket protects the heater from external damage, oil exposure, moisture, and mechanical impact commonly found in extrusion environments.

4. Built-In Thermal Insulation Layer

We integrate an additional ceramic fiber blanket to enhance insulation, increasing energy efficiency and reducing heat radiation into the workplace.

Uniform Heat Distribution for Consistent Melt Quality

Temperature uniformity is critical in extrusion. Uneven heating leads to material degradation, bubbles, inconsistent viscosity, and dimensional variation in the final product. Our ceramic band heaters are designed for even heat distribution across the barrel circumference.

We achieve this through:

- Precisely calculated watt density

- Evenly spaced heating coils

- Close contact design with the barrel surface

- Custom sizing for perfect fit

This ensures that the polymer melt remains stable, resulting in improved product quality and reduced material waste.

Energy Efficiency That Reduces Operating Costs

Energy consumption is a major concern in continuous extrusion operations. Our energy-efficient ceramic band heaters significantly lower heat loss thanks to their superior insulation system.

Efficiency benefits include:

- Faster heating cycles

- Reduced power consumption

- Lower heat radiation into the surrounding area

- Decreased load on cooling systems

By minimizing energy waste, we help extrusion plants improve operational efficiency while maintaining optimal production temperatures.

Custom-Engineered for Every Extrusion Machine

No two extrusion systems are exactly the same. Barrel diameters, heating zones, temperature requirements, and material types vary widely. We offer custom ceramic band heaters for extrusion machines tailored to specific applications.

Customization options include:

- Inner diameter and width as per barrel dimensions

- Voltage options from 110V to 440V

- Wattage design for precise temperature control

- Terminal box or lead wire connections

- Thermocouple holes for accurate sensing

- Special clamping systems for secure mounting

This level of customization ensures optimal heater performance and seamless integration into existing machinery.

High Watt Density for Rapid Heat-Up

Extrusion lines benefit from quick startup times. Our high watt density ceramic band heaters provide rapid heating without compromising longevity. The advanced ceramic insulation prevents overheating and protects the heating element from burnout.

Faster heat-up means:

- Reduced machine downtime

- Quicker production changeovers

- Improved operational efficiency

Durability in Continuous Industrial Operation

Extrusion machines often operate 24/7. Our industrial-grade ceramic band heaters are built to withstand long production runs with minimal maintenance.

Durability features include:

- Resistance to vibration and mechanical stress

- Protection against oil and chemical exposure

- Strong terminal enclosures

- Robust clamping mechanisms

These features reduce the risk of heater failure and ensure stable performance in demanding manufacturing environments.

Easy Installation and Maintenance

We design our ceramic band heaters for extrusion barrels with practical usability in mind. Split construction and adjustable clamping systems make installation quick and secure.

Maintenance is simplified because:

- Heater sections can be replaced individually

- Wiring connections are accessible

- Thermocouple ports are integrated

- Durable construction reduces replacement frequency

This helps minimize downtime and maintenance costs.

Applications Across Extrusion Industries

Our ceramic band heaters are used in a wide range of extrusion processes, including:

- Plastic pipe extrusion

- Sheet and film extrusion

- Profile extrusion

- Cable coating extrusion

- Compounding lines

Each application demands stable temperature control, which our heaters consistently deliver.

Why Our Ceramic Band Heaters Stand Out

We combine precision engineering, high-quality materials, and application-specific design to deliver heaters that perform reliably in extrusion environments.

What sets us apart:

- Tight manufacturing tolerances

- Strict quality testing procedures

- High thermal efficiency

- Long operational life

- Reliable temperature control

Our focus remains on helping extrusion manufacturers achieve higher productivity with reduced operational costs.

Choosing the Best Ceramic Band Heater for Your Extrusion Machine

Selecting the right ceramic band heater depends on barrel size, operating temperature, polymer type, and production speed. We guide customers in choosing heaters that match their exact process needs to ensure maximum performance and longevity.

A well-designed ceramic band heater for extrusion machine improves melt consistency, reduces energy use, and extends machine life — making it a critical component of modern extrusion systems.