As a leading plastic injection molding heater manufacturer, we provide precision-engineered industrial heating solutions that enhance productivity, efficiency, and reliability in plastic processing industries. We design and manufacture band heaters, nozzle heaters, cartridge heaters, and custom industrial heating systems built specifically for demanding injection molding environments. Our expertise lies in delivering consistent thermal performance, energy efficiency, and long operational life for modern production facilities.

High-Performance Heating Technology for Injection Molding

Injection molding requires accurate temperature control, rapid heating cycles, and durable components capable of withstanding continuous industrial use. Our heaters are manufactured using advanced resistance winding techniques, superior insulation materials, and robust protective sheathing to ensure:

- Uniform heat distribution

- Fast thermal response

- High watt density capability

- Reduced energy loss

- Extended operational lifespan

Each product is engineered to maintain process stability while minimizing downtime and maintenance requirements.

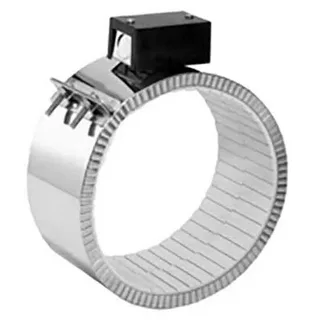

Ceramic Band Heaters for Energy-Efficient Barrel Heating

Our ceramic band heaters are designed for high-temperature barrel heating applications in injection molding machines. Built with interlocking ceramic insulation tiles and nickel-chromium heating elements, these heaters provide:

- Exceptional insulation properties

- Lower power consumption

- Improved heat retention

- Longer service life

The stainless steel outer cover protects against mechanical damage while ceramic insulation significantly reduces heat loss, allowing efficient operation at temperatures up to 600°C.

Mica Band Heaters – Reliable and Economical

We manufacture mica band heaters as a cost-effective heating solution for moderate-temperature applications. Using high-grade mica insulation, precision resistance wire, and stainless steel cladding, these heaters deliver:

- Compact construction

- Excellent heat transfer

- Ease of installation

- Reliable thermal performance

They are widely used for plastic injection molding barrels where steady and controlled heating is required.

Nozzle Heaters for Precise Melt Flow Control

Nozzle zones demand highly accurate temperature control to prevent material solidification and ensure consistent plastic flow. Our nozzle heaters are engineered for superior conductivity and tight fitment. We supply:

- Brass nozzle heaters

- Stainless steel nozzle heaters

- Coil heaters for nozzles

These heaters offer rapid heat-up, stable temperature maintenance, and resistance to repeated thermal cycling.

Cartridge Heaters for Molds and Tooling

Our cartridge heaters provide localized, high-density heating for molds, dies, and hot runner systems. Manufactured using magnesium oxide insulation and precision resistance elements, they ensure:

- Efficient heat transfer

- Mechanical strength

- Vibration resistance

- Corrosion-resistant sheath options

They are essential for maintaining consistent temperatures within mold components.

Advanced Materials and Precision Engineering

We utilize nickel-chromium resistance wire, ceramic insulation, mica sheets, and stainless steel sheathing to ensure heater durability. Every heater undergoes thermal design optimization based on:

- Watt density requirements

- Operating temperature range

- Surface area contact

- Voltage specifications

This engineering approach ensures process reliability and maximum efficiency.

Energy-Efficient Industrial Heating Systems

Energy efficiency directly impacts production cost. Our heaters feature low thermal loss insulation, precision coil spacing, and optimized construction to reduce power consumption, resulting in:

- Lower operating expenses

- Improved production output

- Reduced machine downtime

Custom Heater Manufacturing

We offer fully customized heater solutions tailored to specific machine requirements. Capabilities include:

- Custom diameters and widths

- Variable watt densities

- Specialized terminal types

- Moisture-resistant designs

- High-temperature lead wires

Each heater is manufactured according to exact application needs.

Quality Control and Testing

Strict quality standards ensure every heater meets performance expectations. Testing includes:

- Insulation resistance verification

- Wattage accuracy testing

- Dielectric strength testing

- Dimensional inspection

These processes guarantee safety, consistency, and durability.

Applications in Plastic Processing

Our heating systems are widely used in:

- Injection molding machines

- Extrusion lines

- Blow molding systems

- Hot runner systems

- Packaging machinery

Each application requires stable, high-performance heating under continuous operation.

Durable Construction for Long Service Life

We manufacture heaters with:

- Corrosion-resistant metal sheathing

- High-temperature insulation

- Strong terminal connections

- Mechanical vibration resistance

These features ensure extended operational life and reduced maintenance.

Technical Specifications

- Voltage Range: 110V – 480V

- Maximum Temperature: Up to 600°C

- Sheath Materials: Stainless Steel / Brass

- Insulation: Ceramic / Mica / Magnesium Oxide

- Watt Density: Application specific

Company Profile – Kol-Heater (Kolkata Heater)

We operate as Kol-Heater (Kolkata Heater), a trusted industrial heater manufacturer based in Kolkata. Our manufacturing unit is equipped with advanced production tools and testing facilities to ensure consistent product quality and engineering precision.

While our production facility is located in Kolkata, we supply industrial heaters to machine manufacturers across India. Our focus remains on delivering reliable, long-lasting heaters that meet the performance requirements of modern industrial machinery. We are recognized for durable construction, timely supply, and application-focused heater design.

Contact Information

Kol-Heater (Kolkata Heater)

309 Rabindra Sarani

Kolkata – 700006

India

Phone: +91 9038960476 | +91 9836994384

Email: heaterskolkata@gmail.com

Why Industries Choose Our Heating Solutions

We combine technical expertise, precision manufacturing, and strict quality assurance to deliver high-performance industrial heating solutions. As a leading Plastic Injection Molding Heater Manufacturer, we design and supply heaters that perform reliably under demanding industrial conditions. Our focus on application-specific engineering, consistent quality standards, and nationwide supply capability makes us a preferred partner for plastic processing industries across India.